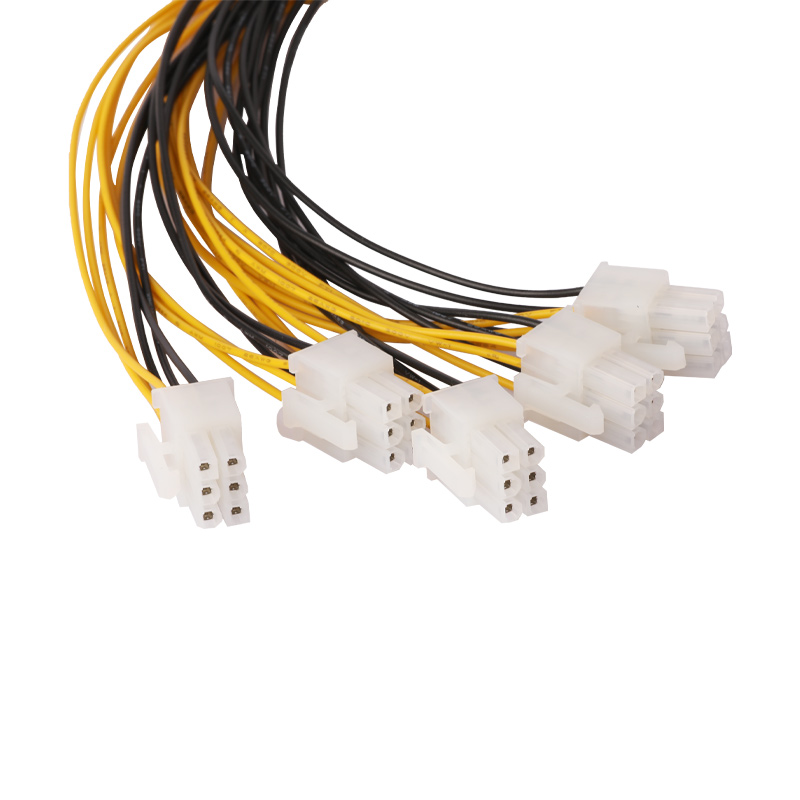

PVC material Car headlight equipment internal wire harness

Detail Introduction

① Non-UL 1007-24AWG wire, L=300mm, the conductor uses tinned copper, PVC environmental protection insulation; rated temperature 80℃, and the rated voltage is 300V;

Product Features And Application

① The male terminal and the female rubber shell are matched with the design, and the parts are used as a whole set to ensure the uniformity of the wiring harness and the uniformity of the connection performance of the electrical equipment.

② The rubber shell and the wire are firmly connected, which reduces the risk of accidental falling off, safe and reliable.

Scenes To Be Used

① Used for internal wiring of automobile headlight equipment.

Materials Type

① The conductor uses tinned copper and PVC environmental protection insulation;

② The plastic shell is made of environmentally friendly ABS material;

③ The terminals are tinned environmentally friendly;

④ RNB14-5-ring is made of high-quality copper material, which has good ductility, good thermal; good electrical conductivity; tin-plated surface, anti-oxidation. Anti-corrosion, there is a ribbed wire in the inner hole of the terminal tail to increase the resistance to pressure, the appearance is beautiful after crimping, and it plays a role of fixing the wire

Production Process

① Using the production process of fully automatic shell-piercing machine;

Quality Control

The products have passed quality control in 100% percentage such as conduction test, withstand voltage test, tensile strength test, etc.

Appearance Requirements

1. The surface of the wire colloid should be smooth, flat, uniform in color, without mechanical damage, and clear in printing

2. The wire colloid must not have the phenomenon of lack of glue, oxygen skin, variegated color, stains and so on.

3. The finished product size must meet the drawing requirements